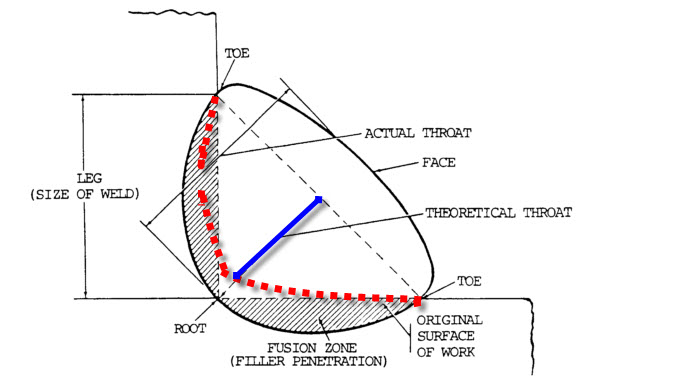

When weld sizes are determined by design engineers, the theoretical throat is used to calculate weld strength which in turn gives our leg size (for fillet welds). This means that the desired strength of a weld is achieved only if we attain fusion to the root and side walls.

The terms fusion and penetration are used interchangeably but they are not the same. AWS defines fusion as “the melting together of filler metal and base material which results in coalescence.” This basically means that the filler metal and base material become one homogenous piece of metal. Penetration, which is also called depth of fusion, is defined by AWS as “the distance that fusion extends into the base metal or previous pass from the surface melted during welding.”

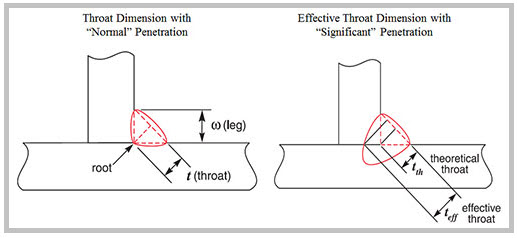

So does depth of penetration affect weld strength? See the image below.

As you can see in the above figure, you can have two welds with equal leg size (fillet leg size) but with different amounts of penetration. If our print calls for a 5/16″ weld we should, at the very least, achieve fusion to the root to get the desired strength. Any amount of penetration beyond the root will increase the effective throat of the weld which in turn increases its strength. So theoretically, a 1/4″ fillet weld can have higher strength than a 5/16″ weld if it achieves significantly deeper root penetration. For an example of this which shows all the strength calculation read Bigger (Weld) Is Not Always Better.

If we don’t achieve root fusion then our 5/16″ fillet weld will not provide the needed strength since our effective throat will be smaller than the theoretical throat which was used to calculate the strength of the weld during the design stage.

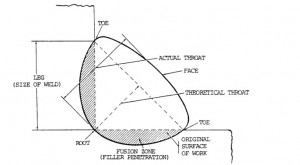

The above figure shows a diagram of a weld with adequate root fusion. This is what we want to see when we do an etching of the cross section of a fillet weld. If we do not have fusion at the root we are prone to weld failure because the weld does not have the strength it was designed to achieve.

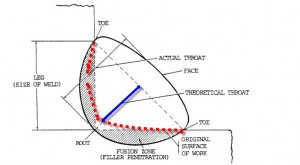

In the above figure the red, dotted line depicts a weld that achieved fusion to the vertical wall but questionable fusion to the horizontal wall. More importantly, this weld did not achieve root fusion and consequently has a much smaller effective throat. The blue line denotes the actual throat. This weld will be much weaker than the one in figure 2. Because the weld does not have the proper strength there is a high probability of failure.

It is important to make sure that you always get fusion at the root. If you are not achieving this you need to adjust your welding parameters. Having welding procedures that achieve proper penetration is absolutely necessary. Procedures should be qualified by testing, or in some cases can be prequalified. If using prequalified welding procedures you must still be careful as there are some dangers to doing this. We recommend you read “Dangers of Using Prequalified Welding Procedures” if you will be going this route.

Source: Fabricators’ and Erectors’ Guide to Welded Steel Construction

Good Info

Very informative posts for people with little Welding knowledge to understand Welding basics. Thanks again and keep up the good work!

Thanks for the comment Junaid. Let us know if you have any questions or topics you would like to see us cover.

Thanks for this page, i learn a lot about my job, i am a welder too, keep up the good work, to share to other about welding process and technics.

Thanks! Glad you are enjoying the content.

Thanks for this

D1.1 AWS 2010