7 Areas of Study for Aspiring Welding Engineers

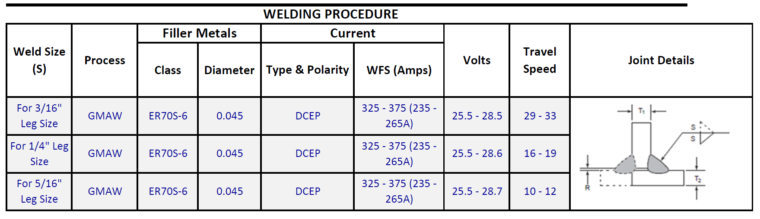

Welding engineering is a complex field that requires expertise in many different engineering disciplines. The welding engineer must take advanced courses in metallurgy (including welding metallurgy), material science, mechanics of materials, thermodynamics, chemistry and fundamentals of all welding processes. Welding engineers are tasked with many different activities which include but are not limited to: […]