10 Types of Welding Discontinuities Explained

Not all discontinuities are defects

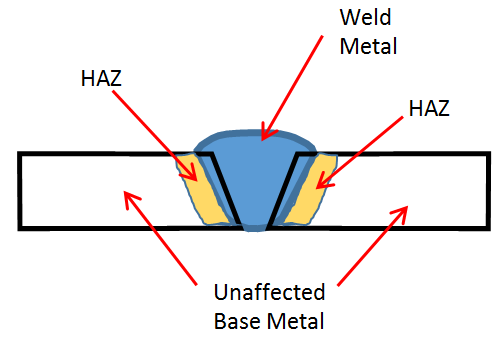

Not all weld discontinuities are weld defects, but all weld defects are discontinuities. Understanding the difference will let you know if you need to scrap a part, repair it or simply add more weld. There are many codes depending on what type of product you are welding on. The codes are used as guidelines by […]