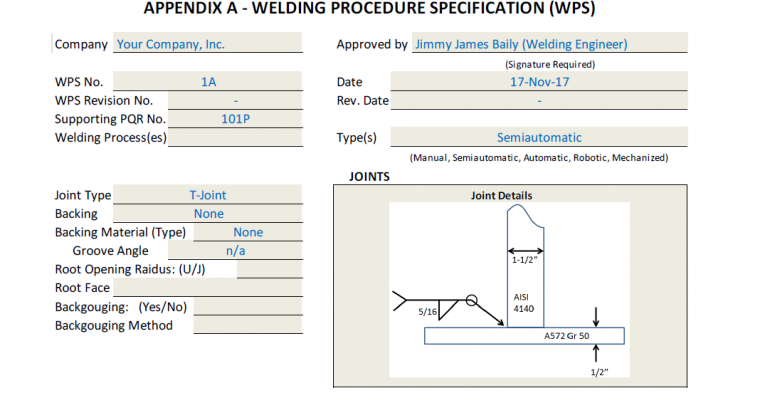

How to Develop a Welding Procedure Specification

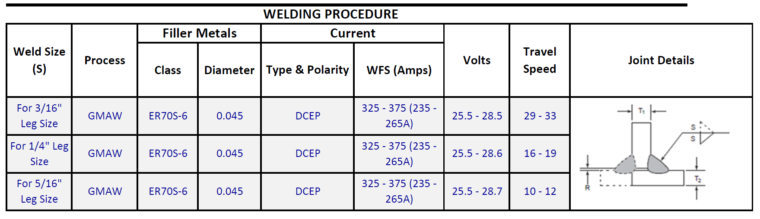

Developing, or writing a welding procedure, goes far beyond setting up amps and volts. It entails the selection of many variables which fall under the 9 required components of welding procedure specifications we discussed last week. Today we look at those 9 components again, but rather than just stating what they contain we explain how […]