5 Factors that Contribute to Silicon Island Formation in Welds

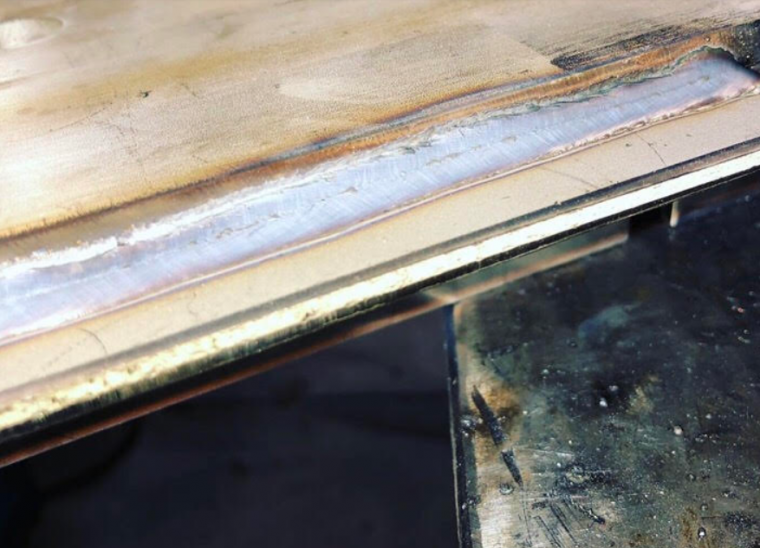

The formation of silicon islands on welds made with the GMAW (mig) and MCAW (metalcore) processes is very common. For the most part, these silicon islands are not a problem. However, if the weld is to be painted, you better remove these islands. Otherwise, they will eventually pop off and leave an unpainted spot in […]